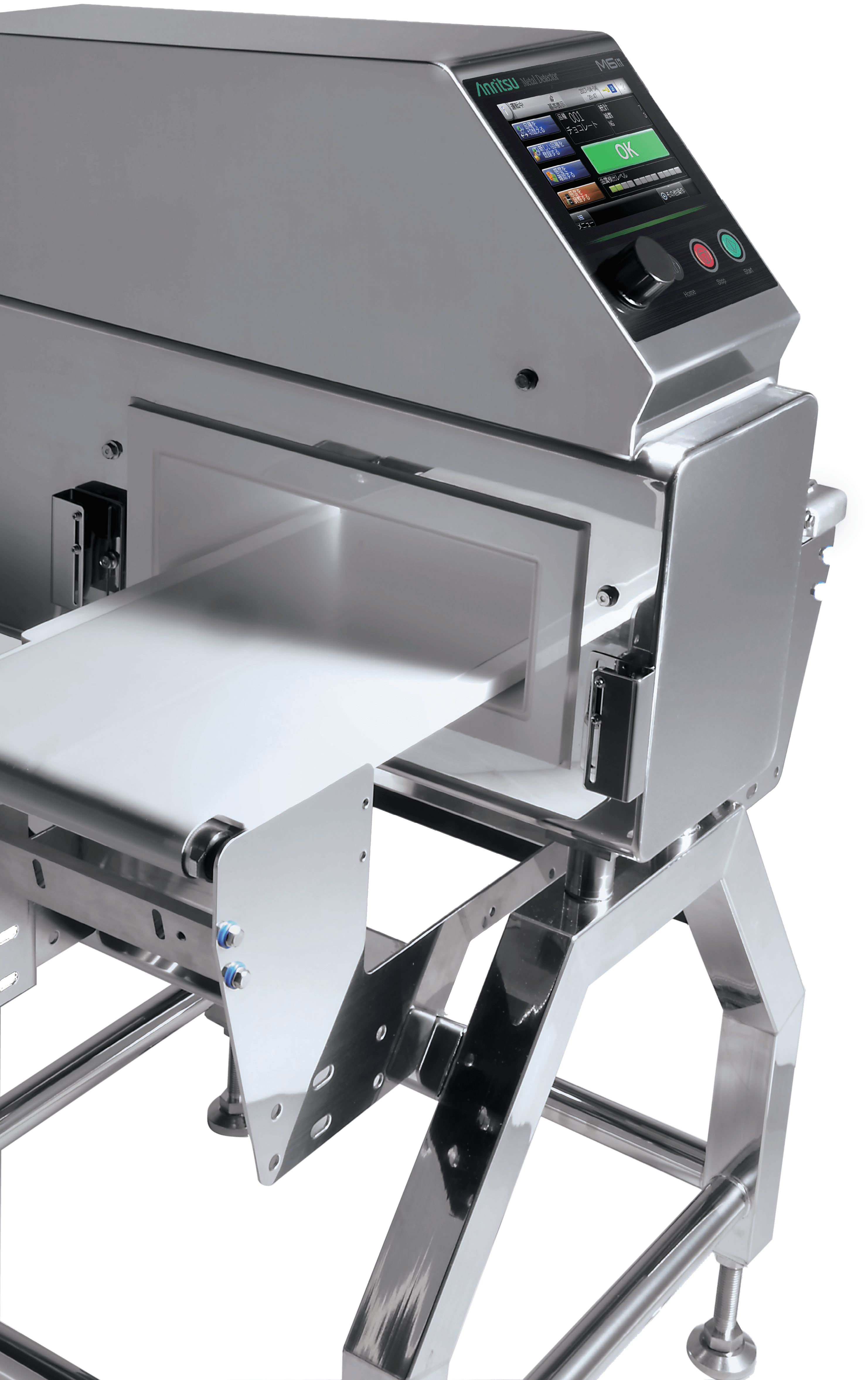

Description

Enhanced Performance – M6-h delivers high detection sensitivity and stability on your production line. Delivering the same detection levels as described in catalogs is a big challenge for metal detection systems when performing the inspection on actual production lines. As detection sensitivity can vary depending on product and environment conditions including temperature and humidity, it can be challenging to provide consistent detection. Anritsu’s M6-h series metal detector is designed to deliver unrivaled levels of detection sensitivity on your production lines. The auto-learn process makes excellent detection quickly achievable.

Features

Advanced Digital Signal Processing

- Built-in digital signal processing (patent pending) better isolates product effect and minimizes its impact on detection. Outstanding detection made easy.

Improved Auto-Learn provides reliable, repeatable performance

- Improvement in detection and performance were developed in-house, using our 50+ years of industry experience. The auto-learn process optimizes the best phase, frequency and detection algorithms for the dual simultaneous frequencies.

Vibration and electrical noise resistant

- Metal detectors look for fluctuations within magnetic fields when the product passes through the detector head. Since the magnetic fields are affected by external sources such as floor vibration and inverters from nearby machines, a metal detector must be designed to handle these challenges. With this in mind, Anritsu’s detection heads are designed to provide high sensitivity without sacrificing repeatability and reliability.

High sensitivity detection of both ferrous and non-ferrous metals

- Anritsu’s patented dual-frequency technology is optimized for both ferrous and non-ferrous metals simultaneously. With the improved auto-learn process, Anritsu systems analyze more than 10,000 combinations of frequencies and algorithms to provide the best detection possible.

Minimize false rejects

- Built-in troubleshooting screens show the possible cause of false rejects and provide on-screen suggestions to improve performance

Benefits

Smart Guide – perfect for HACCP

- Metal detectors are considered a critical control point (CCP) in HACCP programs and require detection checks to make sure they are meeting your standards. Smart Guide directs detection and operation checks in an easy-to understand format. It can be set to stop operation if the testing fails ensuring compliance. Operator training is also minimized.

Reject confirmation

- Contaminated products should not only be detected but also rejected properly. Anritsu’s reject confirmation ensures rejected products are fully removed from the production line.

User levels

- Passwords are required when changing critical product settings including sensitivity changes. This helps avoid human errors and potential operator mistakes. Optional barcode reader simplifies operator identification.

Daily inspection report

- Simplified data and log management allows quick response to retailers or customer quality inquires.

Design verification that meets global standards

- We conduct strict design verifications to meet national and international standards such as CE marking and FCC. Anritsu metal detectors offer reliable solutions for quality control in the food industry around the globe.