In today’s manufacturing industry, ensuring product safety and quality is paramount. A single contaminant can ruin a brand’s reputation and lead to costly product recalls. Hence, industries are in need of efficient and reliable inspection systems to detect contaminants, including those that are difficult to identify with the naked eye. This is where Anritsu, the leading provider of industrial inspection systems, comes into play.

Best-In-Class Inspection Capability

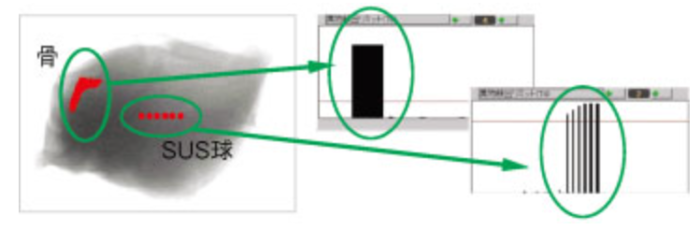

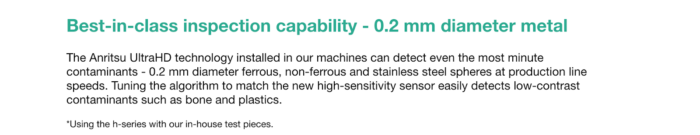

Anritsu’s x-ray inspection systems are designed to detect low-density contaminants, such as stone, glass, and bone, in addition to metal fragments. The company’s UltraHD technology can detect even the tiniest contaminants of 0.2 mm diameter ferrous, non-ferrous, and stainless steel spheres at production line speeds. Furthermore, the algorithm can be easily tuned to match the new high-sensitivity sensor, making it capable of detecting low-contrast contaminants like bone and plastics.

Reference for Jovan:

X-Ray System or Metal Detector: Which is best for you?

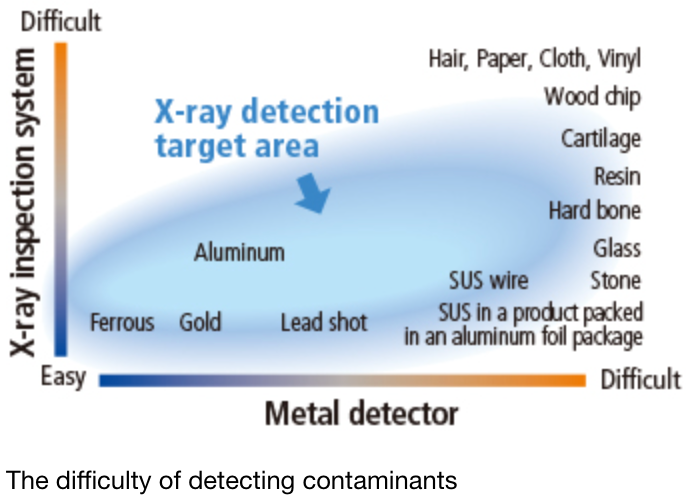

When it comes to selecting the appropriate industrial inspection system, the type of likely contaminants needs to be considered. While Anritsu’s industrial x-ray systems can detect a wide range of contaminants, including those that metal detectors cannot, metal detectors can detect the entire range of metals, including ferrous, non-ferrous, and aluminum. Thus, the decision of whether to use an x-ray system or metal detector will depend on the specific needs of the industry.

However, with Anritsu’s UltraHD technology, the industrial x-ray system may be the better choice for detecting low-density contaminants. The 0.2 mm diameter metal detection capability of Anritsu’s industrial inspection machines is best-in-class, ensuring that even the smallest contaminant can be detected before it reaches the consumer.

One of the most significant advantages of Anritsu’s inspection system is its ability to detect contaminants at production line speeds, ensuring minimal disruption to the manufacturing process. With the machine installed at various stages of production, the contaminant can be identified and eliminated before the product reaches the next stage, thereby preventing the spread of contamination.

In conclusion, detecting contaminants in the production line is crucial for maintaining product quality and ensuring customer safety. With Anritsu’s UltraHD technology, industries can detect even the most minute contaminants, such as bone and plastics, with ease. The x-ray inspection system is best suited for detecting low-density contaminants, such as stone, glass, and bone,

in addition to metal fragments, and can be easily integrated into existing production lines. Anritsu’s inspection system is undoubtedly the way to go for industries that value efficiency, reliability, and customer safety.

Factronics USA is a proud distributor of Anrtisu’s Food & Pharmaceutical industrial inspection equipment.

About Anritsu

For nearly half a century, Anritsu Infivis has been designing superior detection and inspection equipment for food, pharmaceutical and chemical packaging and processing industries. Across the globe, we provide a superior return on investment while ensuring our clients are in compliance with the most stringent quality control programs. No other company provides better support, experience and technology to detect contaminants or quality issues within products. With more than 150,000 installations globally, and our development of strong quality control relationships with customers, Anritsu has a proven commitment to making food and pharmaceutical products safer at a higher level of quality assurance than competitors. At the forefront of detection technology, our X-ray inspection systems, Checkweighers, Metal Detectors and Performance 360™ Service, Training and Performance Assurance programs give you the tools you need to produce products efficiently and safely. To learn more, please contact Factronics USA at (305) 888-6714 today!