As of April 1, 2023, Costco will require food product suppliers to have a comprehensive foreign material control program. The Costco Food Safety Program is starting to require X-Ray inspection for most finished products. Now is the time to start exploring X-Ray inspection and how it can help your business and HACCP program – Factronics USA has the solution for you!

In the food industry, ensuring the safety and quality of products is paramount. Contaminants and foreign materials pose a significant risk, leading to potential recalls, legal issues, and damage to brand reputation. To address these concerns, Anritsu, our supplier and a leader in detection/inspection equipment, has developed the XR75 DualX X-Ray system. This cutting-edge technology provides accurate and reliable food product inspection and contaminant detection, minimizing false rejects and improving overall food safety. In this article, we will explore the features, benefits, and world-class reliability of the Anritsu XR75 DualX X-Ray system.

Evolution with New Dual Energy Senor

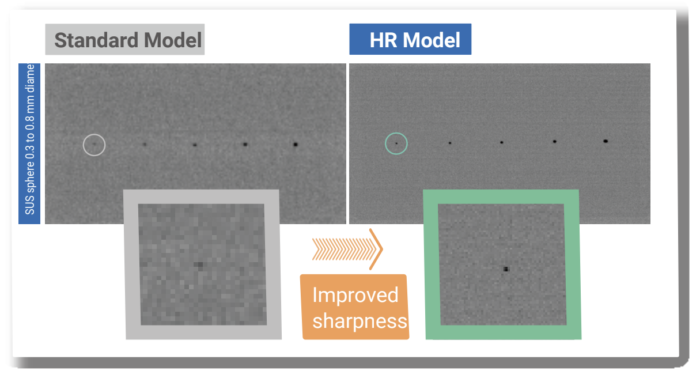

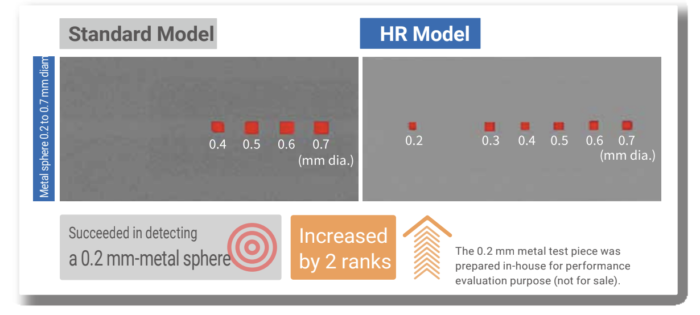

The new sensor within the XR-75 DualX X-Ray has enabled high resolution images to be obtained and improved the detection performance of fine metals and small bones. The dual energy system also significantly reduces the effects of products with rough surfaces, detecting even low-density contaminants. Especially for meat applications thicker than 40 mm, there is a noticeable difference compared to the conventional dual energy model.

Dedicated Detection Algorithms

The detection algorithms are tuned and optimized for high-resolution images obtained from the new sensor. Each algorithm has been developed and installed for different characteristics of product and target contaminants, which results in improved detection sensitivity and reduced false rejections.

Accurate and Reliable Contaminant Detection

The XR75 DualX X-Ray system utilizes advanced XR75 technology, analyzing two X-ray signals, both high and low energy, to achieve a higher detection rate for low-density items and foreign materials. The system can detect contaminants as small as 0.4mm, making it highly effective in identifying even the tiniest contaminants in food products.

One of the key advantages of DualX technology is its ability to detect soft contaminants, such as bones in poultry, stone, glass, rubber, and metal. This capability is especially crucial for products with overlapping pieces in a pack or bag, including fries, frozen vegetables, and chicken nuggets, among others.

Key Benefits of Anritsu XR75 DualX:

- 1. Minimize False Rejects: With its precise and reliable detection capabilities, the XR75 DualX technology significantly reduces false rejects, ensuring that only contaminated products are rejected, leading to less waste and improved production efficiency.

- 2. Reliable Detection of Thin, Low-Density Bones: The DualX solution excels in detecting thin, low-density bones, providing an added layer of safety for consumers and enhancing product quality.

- 3. High Detection Sensitivity for Overlapping Food Products: The system’s high detection sensitivity is particularly beneficial for products with overlapping pieces, guaranteeing that even the smallest contaminants are detected and eliminated.

- 4. Ease of Use and Setup: Anritsu prioritizes user-friendliness, and the XR75 DualX system is no exception. It features an auto-learn product setup wizard, making it simple for operators to configure the system for different products quickly.

- 5. Compatibility with QuiCCA3: Anritsu’s Overall Quality Control and Management System, QuiCCA3, seamlessly integrates with the XR75 DualX, streamlining quality control processes and enhancing the overall inspection efficiency.

- 6. Low Total Cost of Ownership: The XR75 DualX is built with Anritsu A.L.L. (Advanced Long Life) technology, incorporating long-life, low-power components. This design reduces heat generation, eliminates the need for a cooling system, and lowers power consumption, resulting in reduced lifetime operating costs.

Safety of Inspected Products

WHO concluded in 1980 that the “irradiation of any food commodity up to an overall average dose of 10 kGy presents no toxicological hazard and introduces no special nutritional or microbiological problems.”

The maximum dose of x-ray irradiation to the products to be inspected by our x-ray inspection systems is 0.002 Gy, which is much lower than the value described above. Even if a product stops inside, the x-ray dose is always kept to 0.1 Gy or less.

**Gy (gray) = The new international system (SI) unit of radiation dose, expressed as absorbed energy per unit mass of tissue. The SI unit “gray” has replaced the older “rad” designation. 1 Gy = 1 Joule/kilogram = 100 rad.**

Ease of Use and Maintenance

Anritsu’s installations are designed to be easy-to-use and easy-to-understand, allowing operators to navigate the system efficiently without extensive technical knowledge. The system’s graphical interface and color-coded algorithm feedback provide operators with essential information to create new products and adjust settings with ease.

Additionally, the XR75 DualX’s reliability minimizes the need for maintenance. When maintenance is required, the system offers a full suite of diagnostics and plug-and-play boards, along with an easy-release conveyor design, to facilitate quick maintenance and reduce downtime.

The Anritsu XR75 DualX X-Ray system represents a significant advancement in food inspection and contaminant detection technology. Its ability to analyze two X-ray signals and detect soft contaminants and thin, low-density bones sets it apart from standard X-ray systems. With its accurate and reliable performance, the XR75 DualX minimizes false rejects, reduces operational costs, and enhances food safety in high-speed production environments.

Anritsu’s world-class reliability, ease of use, and maintenance further contribute to its appeal, making it a preferred choice for the food industry. As the demand for safer and higher-quality products continues to rise, the XR75 DualX remains at the forefront of ensuring food safety and protecting brand reputation in the global market.

Contact Factronics USA today at (305) 888-6714 for a FREE demo with our local service reps. We guarantee superb service backed by integrity and expertise. We can assist you in picking out the industrial inspection system that is best suited for your application – working to get you both the best products and service at the best price.

About Factronics USA

Founded in the year 2000, Factronics USA is a trusted provider of cutting-edge packaging coding solutions and inspection systems. With over 35 years of industry experience, we specialize in delivering high-quality and reliable industrial printing solutions that enhance business performance across a diverse range of industries, materials, and operational needs.

At Factronics USA, we understand the critical role that efficient industrial equipment plays in enhancing productivity. Our comprehensive portfolio encompasses a wide array of industrial equipment solutions tailored to meet the unique requirements of manufacturing processes and beyond. From food and beverage packaging to precision medical equipment, our innovative printing and packaging solutions are designed to elevate speed and efficiency within your workspace.

As part of our commitment to excellence, Factronics USA proudly partners with industry leaders like Anritsu to provide top-tier solutions. The Anritsu brand embodies the pinnacle of quality and innovation in the field of industrial inspection. By integrating Anritsu products into our offerings, we ensure that our customers benefit from state-of-the-art technology that simplifies their industrial equipment needs.

Our dedicated team is committed to simplifying the industrial equipment procurement process for our customers. From initial consultation to implementation and ongoing support, Factronics USA is here to guide you every step of the way. We believe that industrial equipment should not be a source of complexity but rather a catalyst for your success.

Experience the difference with Factronics USA and discover how our partnership with Anritsu can transform your operations. Contact us today to find the perfect solution that meets your specific requirements, and let us assist you from start to finish!