The Linx UVG5 UV laser is specifically designed for permanent marking on complex materials such as delicate mono-recyclable films and rigid plastics, including HDPE, LDPE, and PP. By minimising thermal stress, each coder ensures substrate integrity and reduces the risk of damage, making it an ideal choice for marking sensitive materials where traditional CO2 and fibre lasers may cause undesirable effects.

Capable of coding up to 2,000 characters per second, the Linx UVG5 coder provides permanent, high contrast marking. Fast and consistent coding maximises production throughput while supporting traceability with both human-readable and machine-readable codes, including 2D Data Matrix, and QR including GS1 formats.

By eliminating the need for consumables, the UVG5 laser reduces both the cost of ownership and the need for ongoing monitoring. This contributes to a more sustainable solution while minimising downtime and maximising operator efficiency. The integrated Focus Shift technology allows for marking on multi-sized products on a single production line without the need for manual adjustments, reducing setup times and enhancing production line flexibility.

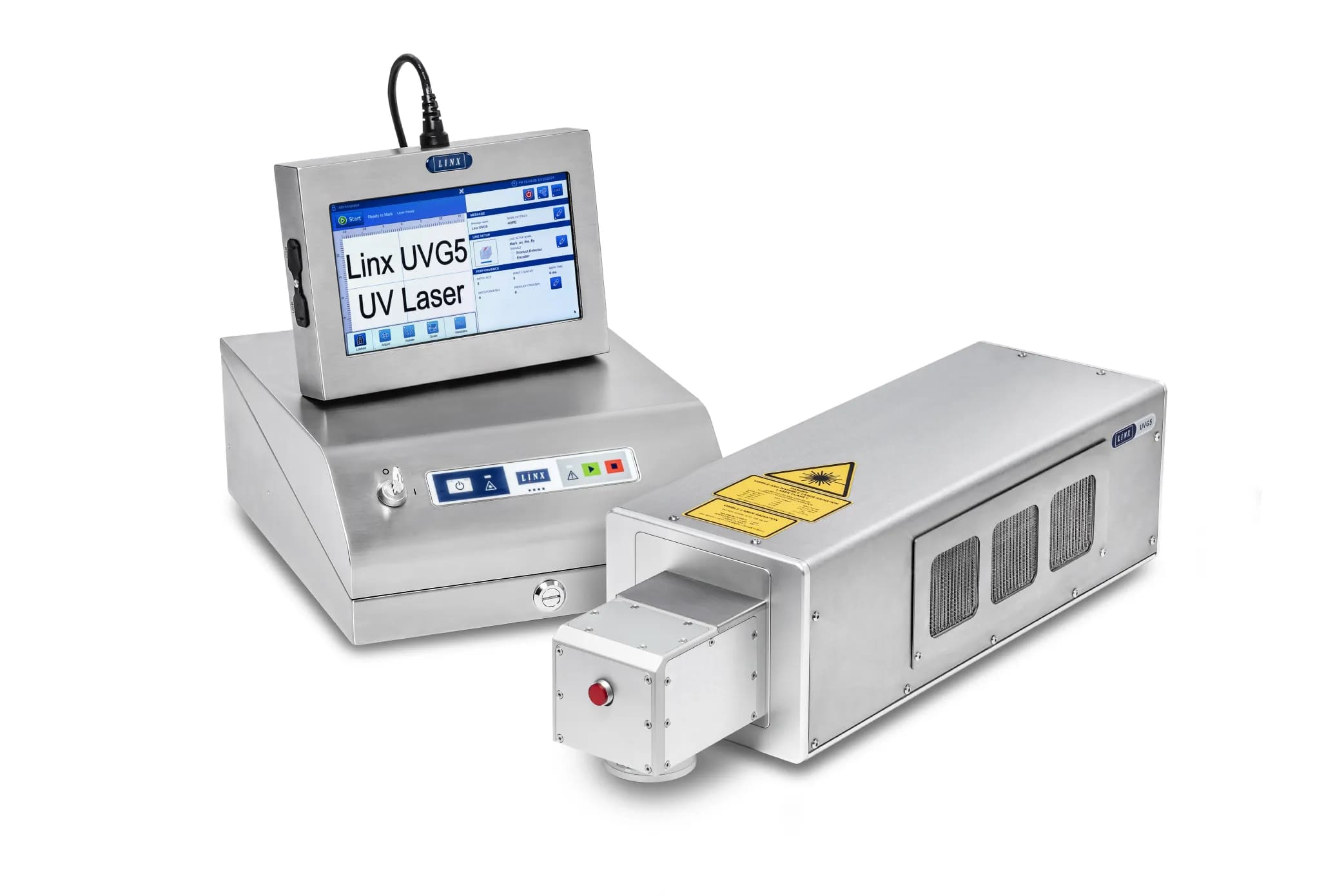

Furthermore, the Linx UVG5 laser coder’s class leading enhanced integration and flexibility make it suitable for a wide range of applications. With various adaptable beam delivery options, it seamlessly integrates into existing production lines and can be installed in space-restricted areas. The user-friendly LinxVision interface simplifies operation and reduces the chance of errors, allowing operators to maintain consistent production with minimal training. While the built-in Pilot Laser and Focus Finder features streamline the setup process, ensuring accurate placement and reducing waste.