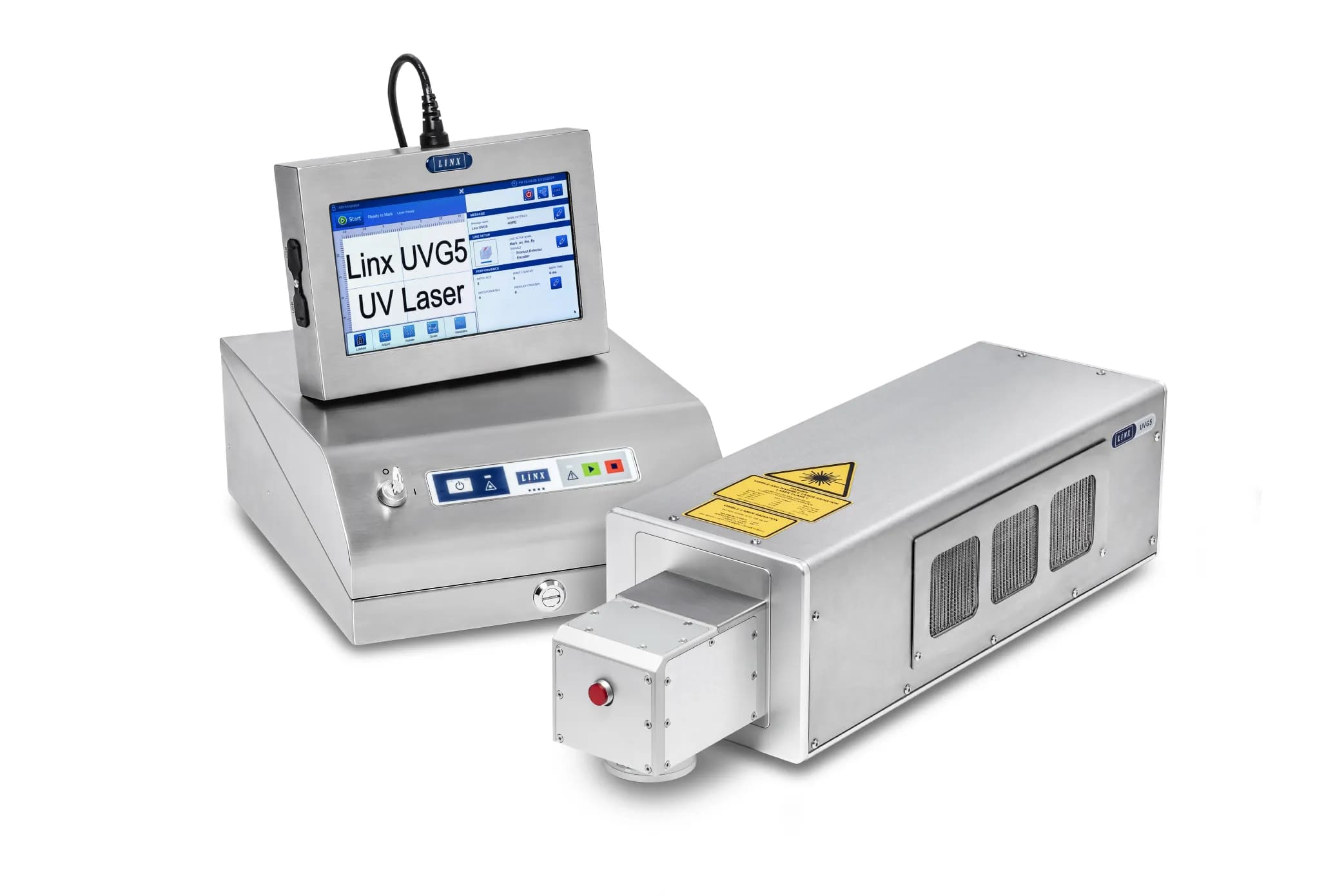

The Linx UVG5 UV laser coder is the ideal solution for permanent marking on flexible films and rigid plastics, without the need for consumables and whilst maintaining the integrity of the substrate. Providing higher production throughput through fast product marking, and with simple integration into existing lines, the easy-to-use Linx UVG5 laser redefines efficiency.

For more information or to speak to our team about whether the Linx UVG5 is right for your needs.

UV lasers are different to other marking lasers such as CO2 and fibre. UV uses high-energy photons to break chemical bonds in materials, a process known as ‘cold processing’, which minimises thermal damage to surrounding areas.

By minimising thermal stress, UV laser marking ensures substrate integrity and reduces the risk of damage, making it an ideal choice for marking sensitive materials where traditional CO2 and fibre lasers may cause undesirable effects.

Error: Contact form not found.