Irish Distillers, Ireland’s leading supplier of wines and spirits and the producer of renowned Irish whiskeys such as Jameson, has implemented Linx CSL30 and CSL60 laser technologies to reinforce brand identity and combat counterfeiting. This initiative ensures that every bottle of Jameson is authentic and of the highest quality.

Protection and Authenticity

Alcohol counterfeiting is a global issue affecting both consumers and producers. Counterfeit whiskey can be harmful to consumers and can damage the reputation of premium brands. Irish Distillers needed a marking solution that was:

- Difficult to replicate, ensuring that counterfeiters could not easily copy their branding.

- Capable of high-speed production, integrating seamlessly into their bottling process

- Permanent and precise, ensuring durability and clarity on glass surfaces.

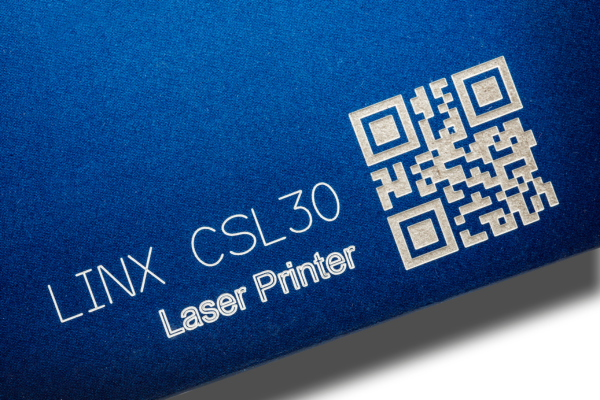

The Solution: Linx CSL30 and CSL60 Laser Coders

After evaluating various options, Irish Distillers selected Linx CSL30 and CSL60 laser coders. These machines apply a “seal of approval” across the bottle cap, glass, and label, ensuring perfect alignment and a highly visible, permanent mark. This mark serves two purposes:

- Authenticity Verification: It certifies that each bottle is genuine and meets Jameson’s quality standards.

- Counterfeit Prevention: The laser mark is impossible to remove without damaging the bottle, making counterfeiting extremely difficult.

Key Benefits of Linx CSL30 and CSL60

1. Permanent, High-Quality Marking

Unlike ink-based coding, which can fade or be removed, laser marking is permanent. Linx lasers provide crisp, durable codes even on difficult surfaces like glass, ensuring long-lasting traceability.

2. High-Speed, Efficient Production

The Linx CSL30 and CSL60 coders can mark at speeds of up to 900 meters per minute, making them ideal for high-volume production lines like those at Irish Distillers. They integrate seamlessly into the bottling process without causing slowdowns.

3. Cost-Effective and Eco-Friendly

Unlike inkjet printers, laser coders do not require consumables such as inks or solvents, making them more sustainable and reducing operational costs. This aligns with Irish Distillers’ commitment to environmentally friendly production.

4. Flexibility and Adaptability

Linx laser coders can mark a wide variety of substrates, including glass, rubber, and plastic. Their adaptability allows them to be used across different packaging formats, ensuring consistency in branding.

Conclusion

By adopting Linx CSL30 and CSL60 laser coding technology, Irish Distillers has significantly enhanced brand protection and product authenticity. This implementation is a prime example of how innovative technology can solve critical challenges in the alcoholic beverage industry, safeguarding both consumers and premium brands from counterfeiting threats.